SL 841 C

Combined TPE/PUR motor connection cable with overall copper screen 0.6/1 kV

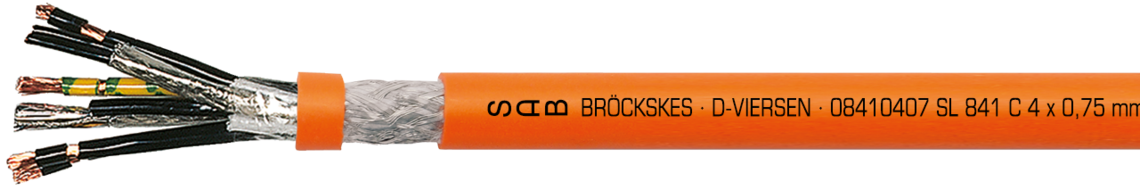

Marking for SL 841 C 08410407: SAB BRÖCKSKES · D-VIERSEN · 08410407 SL 841 C 4 x 0,75 mm² (1000V) + 2 x (2 x 0,34 mm²) (300V) UL AWM Style 20235 80°C CSA AWM I/II A/B 80°C 300V FT1 FT2 CE

Application

SL 841 C is a combined TPE/PUR motor connection cable with high flexibility and overall copper screen 0.6/1 kV. It is recommended for use in highly flexible cable track applications in intelligent industries with servo drives, e.g. automation technologies, machine construction, construction of industrial robots and plants, motive power, control and manufacturing engineering, in handling systems, car manufacturing industry, in cable tracks on wood-working centres, and colour coding acc. to DESINA.

Outstanding features

- UL recognized, CSA approval

- very good EMC characteristics

- long service life

- adhesion-free installation

- high flexibility

- suitable for cable tracks

- halogen-free

- PWIS uncritical (PWIS= paint-wetting impairment substances)

- flexible at low temperatures

- DESINA® colours

Additional information

Cable harnessing possible on request

Construction

| Conductor | bare copper strands acc. to IEC 60228, EN 60228, VDE 0295, class 6 < 0,50 mm² with reference to DIN VDE 0812 |

|---|---|

| Insulation | TPE |

| Colour code | black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334 and a green-yellow earth wire

from item no. 08411415: supply cores: * U1, V2, W3 and a green-yellow earth wire control cores: ** BR1 and BR2 |

| Stranding | control cores 0,34 mm² - 2,5 mm² twisted to pairs |

| Screen | pairs wrapped with alu foil, tinned copper braiding |

| Wrapping | pairs with PETP foil |

| Stranding | screened control pairs and supply cores twisted together in layers |

| Wrapping | two layers non-woven tape |

| Screen | overall copper screen |

| Wrapping | non-woven tape |

| Sheath material | PUR, TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 with mat surface |

| Sheath colour | orange (RAL 2003) |

bare copper strands acc. to IEC 60228, EN 60228, VDE 0295, class 6

< 0,50 mm² with reference to DIN VDE 0812

TPE

black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334

and a green-yellow earth wire

from item no. 08411415:

supply cores: * U1, V2, W3 and a green-yellow earth wire

control cores: ** BR1 and BR2

control cores 0,34 mm² - 2,5 mm² twisted to pairs

pairs wrapped with alu foil, tinned copper braiding

pairs with PETP foil

screened control pairs and supply cores twisted together in layers

two layers non-woven tape

overall copper screen

non-woven tape

PUR, TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 with mat surface

orange (RAL 2003)

Technical data

| Nominal voltage | supply cores Uo/U 0,6/1 kV |

|---|---|

| Peak operating voltage | control cores max. 350 V |

| Voltage UL/CSA | supply cores 1000 V control cores 300 V |

| Testing voltage | supply cores core/core 4000 V core/screen 4000 V

control cores core/core 2000 V core/screen 2000 V |

| Min. bending radius | fixed laying: 5 x d flexible application: 10 x d continuously flexible: 12 x d |

| Radiation resistance | 5 x 10⁷ cJ/kg |

| Temperature range | fixed laying: -50/+90 °C flexible application: -40/+90 °C UL/CSA up to +80 °C |

| Fire performance | flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2, UL FT1, CSA FT1, FT2 |

| Oil resistance | very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| Chem. resistance | good against acids, alkalines, solvents, hydraulic liquids, etc. |

| Weather resistance | very good |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

supply cores Uo/U 0,6/1 kV

control cores max. 350 V

supply cores 1000 V

control cores 300 V

supply cores

core/core 4000 V

core/screen 4000 V

control cores

core/core 2000 V

core/screen 2000 V

fixed laying: 5 x d

flexible application: 10 x d

continuously flexible: 12 x d

5 x 10⁷ cJ/kg

fixed laying: -50/+90 °C

flexible application: -40/+90 °C

UL/CSA up to +80 °C

flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2,

UL FT1, CSA FT1, FT2

very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2

good against acids, alkalines, solvents, hydraulic liquids, etc.

very good

acc. to RoHS directive of the European Union

Dimensions

| item no. | Description | Dimension |

Largest single wire-ø | Outer-ø | Copper figure | Cable weight ≈ | |

|---|---|---|---|---|---|---|---|

| L08410407 | 4 x 0,75 mm² + 2 x (2 x 0,34 mm²) | 0,16/0,11 mm | 11,6 ± 0,5 mm | 117,1 kg/km | 168 kg/km | Send inquiry | |

| L08410410 | 4 x 1,00 mm² + 2 x (2 x 0,75 mm²) | 0,16 mm | 11,8 ± 0,5 mm | 150,1 kg/km | 201 kg/km | Send inquiry | |

| L08410415 | 4 x 1,50 mm² + 2 x (2 x 0,75 mm²) | 0,16 mm | 12,3 ± 0,5 mm | 170,1 kg/km | 228 kg/km | Send inquiry | |

| L08410425 | 4 x 2,50 mm² + 2 x (2 x 1,00 mm²) | 0,16 mm | 14,5 ± 0,8 mm | 231,8 kg/km | 320 kg/km | Send inquiry | |

| L08410441 | 4 x 4,00 mm² + (2 x 1,00 mm²) + (2 x 1,50 mm²) | 0,16 mm | 17,4 ± 0,6 mm | 343,0 kg/km | 458 kg/km | Send inquiry | |

| L08410461 | 4 x 6,00 mm² + (2 x 1,00 mm²) + (2 x 1,50 mm²) | 0,21/0,16 mm | 18,9 ± 0,8 mm | 432,8 kg/km | 557 kg/km | Send inquiry | |

| L08410471 | 4 x 10,00 mm² + (2 x 1,00 mm²) + (2 x 1,50 mm²) | 0,21/0,16 mm | 20,4 ± 1,0 mm | 603,7 kg/km | 736 kg/km | Send inquiry | |

| L08410485 | 4 x 16,00 mm² + 2 x (2 x 1,50 mm²) | 0,21/0,16 mm | 26,0 ± 0,8 mm | 875,7 kg/km | 1111 kg/km | Send inquiry | |

| L08410490 | 4 x 25,00 mm² + 2 x (2 x 1,50 mm²) | 0,21/0,16 mm | 29,4 ± 0,8 mm | 1251,1 kg/km | 1517 kg/km | Send inquiry | |

| L08410495 | 4 x 35,00 mm² + 2 x (2 x 1,50 mm²) | 0,21/0,16 mm | 31,3 ± 0,8 mm | 1644,6 kg/km | 1882 kg/km | Send inquiry | |

| L08410496 | 4 x 50,00 mm² + 2 x (2 x 2,50 mm²) | 0,31/0,16 mm | 38,2 ± 0,8 mm | 2317,6 kg/km | 2659 kg/km | Send inquiry | |

| L08411415 | 4 x 1,50 mm² + (2 x 1,50 mm²) | 0,16 mm | 12,5 ± 0,3 mm | 159,9 kg/km | 222 kg/km | Send inquiry | |

| L08411425 | 4 x 2,50 mm² + (2 x 1,50 mm²) | 0,16 mm | 13,3 ± 0,4 mm | 204,8 kg/km | 285 kg/km | Send inquiry | |

| L08411440 | 4 x 4,00 mm² + (2 x 1,50 mm²) | 0,16 mm | 15,2 ± 0,4 mm | 268,8 kg/km | 369 kg/km | Send inquiry | |

| L08411460 | 4 x 6,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 16,6 ± 1,1 mm | 377,5 kg/km | 485 kg/km | Send inquiry | |

| L08411470 | 4 x 10,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 19,5 ± 1,6 mm | 555,8 kg/km | 677 kg/km | Send inquiry | |

| L08411480 | 4 x 16,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 23,7 ± 1,0 mm | 814,8 kg/km | 1019 kg/km | Send inquiry | |

| L08411490 | 4 x 25,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 27,2 ± 0,7 mm | 1175,6 kg/km | 1418 kg/km | Send inquiry | |

| L08411495 | 4 x 35,00 mm² + (2 x 1,50 mm²) | 0,21/0,16 mm | 30,1 ± 1,0 mm | 1586,4 kg/km | 1810 kg/km | Send inquiry | |

| L08411496 | 4 x 50,00 mm² + (2 x 1,50 mm²) | 0,31/0,16 mm | 34,4 ± 1,0 mm | 2192,4 kg/km | 2463 kg/km | Send inquiry |

wire-ø

Other dimensions and colours are possible on request.