Application

GP 400 Sy - PUR: The high-quality 400 Hz cable for fixed FEGP installations at airports

As a symmetrically designed 400 Hz power supply solution, the GP 400 Sy – PUR cable was developed specifically for fixed electrical ground power (FEGP) applications, such as between a 400 Hz generator and a cable dispenser at the gate. Its robust PUR outer sheath and SABIX® insulation guarantee a long service life and operational reliability even under extreme conditions:

This cable features:

- Low capacitance, ideal for high frequencies with minimal contact resistance

- Temperature resistance from approx. –50°C to +90°C when installed in a fixed position

- Test voltage of up to 4000 V AC between conductors

- Compliance with CE and RoHS standards, supplemented by site safety thanks to halogen-free materials

In the long term, the GP 400 Sy PUR cable not only reduces maintenance and replacement costs, it also makes a significant contribution to reducing emissions, as APUs or mobile GPUs on the ground are no longer required. Thanks to its robust design, it is the ideal choice for permanently installed power supply systems in airport operations and provides long-term support for modern FEGP infrastructures.

Construction

| Conductor | tinned copper strands, fine wires acc. to IEC 60228 class 5 |

|---|---|

| Insulation | SABIX® |

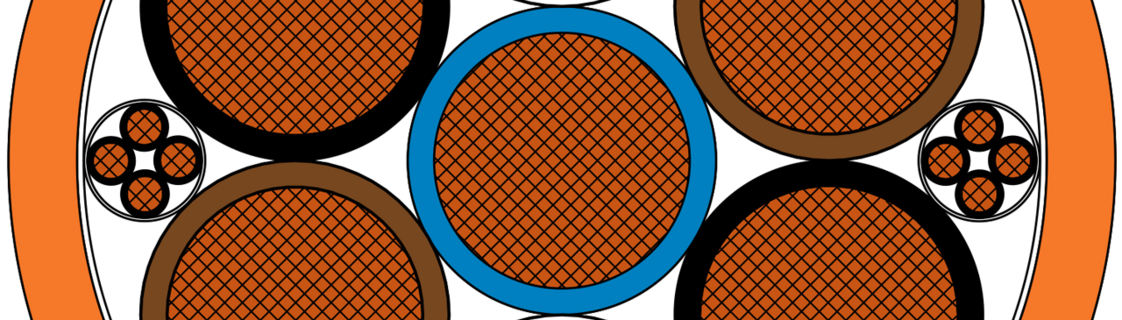

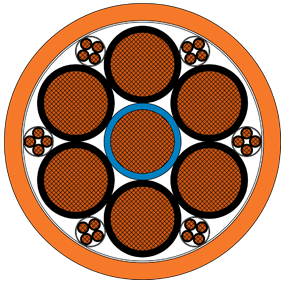

| Colour code 34000452 | 1,0 mm²: black with numbers 1 – 24 35,0 mm²: blue, 2 x white, 2 x brown, 2 x black |

| Colour code 34000453 | 1,0 mm²: black with numbers 1 – 24 50,0 mm²: blue, black with numbers |

| Stranding | 1,0 mm²: each four cores twisted in layers, wrapped with non-woven tape Elements and 50,0 mm² cores twisted in layers, blue core in the centre, wrapped with non-woven tape |

| Outer Sheath | PUR, orange |

tinned copper strands, fine wires acc. to IEC 60228 class 5

SABIX®

1,0 mm²: black with numbers 1 – 24

35,0 mm²: blue, 2 x white, 2 x brown, 2 x black

1,0 mm²: black with numbers 1 – 24

50,0 mm²: blue, black with numbers

1,0 mm²: each four cores twisted in layers, wrapped with non-woven tape

Elements and 50,0 mm² cores twisted in layers, blue core in the centre, wrapped with non-woven tape

PUR, orange

Technical data

| Nominal voltage | 1,0 mm²: Uo/U 115/200 V 50,0 mm²: Uo/U max. 0,6/1 kV |

|---|---|

| Testing voltage | core/core 4000 V AC 50 Hz |

| Min. bending radius | fixed laying: 4 x d flexible application: 6 x d for one single bend: 3 x d |

| Halogen-free | acc. to IEC 60754-1 |

| Temperature range | fixed laying: -50/+90 °C flexible application: -40/+90 °C +110 °C (bis 7500 h) limited time of use |

| Fire performance | sheath material: UL 94 V2 |

| Chemical resistance | good against acids, alkalines, solvents, hydraulic liquids, etc. |

| Hydrolysis and microbial resistance | very good - acc. to EN 50363-10-2 |

| Salt water resistance | very good - acc. to UL 1309 |

| Oil resistance | very good - acc. to EN 50363-10-2 |

| MUD resistance | very good - acc. to IEC 60092-360 |

| Weather resistance | very good - acc. to HD 605 (VDE 0276-605) |

| Ozone resistance | very good - acc. to EN 50396 |

| Abrasion | acc. to UL 2556-2021 and JIS C3005 |

| Fuel resistant | petrol, diesel and kerosene (Jet A-1) |

| Mechanical resistance | characteristics of the PUR outer sheath: - high tensile strength - high tear strength - high abrasion resistance - high notch resistance - high shear strength |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

1,0 mm²: Uo/U 115/200 V

50,0 mm²: Uo/U max. 0,6/1 kV

core/core 4000 V AC 50 Hz

fixed laying: 4 x d

flexible application: 6 x d

for one single bend: 3 x d

acc. to IEC 60754-1

fixed laying: -50/+90 °C

flexible application: -40/+90 °C

+110 °C (bis 7500 h) limited time of use

sheath material: UL 94 V2

good against acids, alkalines, solvents, hydraulic liquids, etc.

very good - acc. to EN 50363-10-2

very good - acc. to UL 1309

very good - acc. to EN 50363-10-2

very good - acc. to IEC 60092-360

very good - acc. to HD 605 (VDE 0276-605)

very good - acc. to EN 50396

acc. to UL 2556-2021 and JIS C3005

petrol, diesel and kerosene (Jet A-1)

characteristics of the PUR outer sheath:

- high tensile strength

- high tear strength

- high abrasion resistance

- high notch resistance

- high shear strength

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section | Approx. outer-ø | Copper figure | Cable weight ≈ |

Ohmic resistance max. Ω/km | |

|---|---|---|---|---|---|---|

| L34000452 | 7 x (35,0 mm² + 6 x 4 x 1,0 mm²) | min. 40 mm - max. 41,9 mm | 2583 kg/km | 3219 kg/km | 35,0 mm²: 0,554 Ω/km | 1,0 mm²: 19,5 Ω/km | Send inquiry |

| L34000453 | 7 x (50,0 mm²+ 6 x 4 x 1,0 mm²) | min. 40 mm - max. 41,9 mm | 3590 kg/km | 4123 kg/km | 50,0mm²: 0,386 Ω/km | 1,0 mm²: 20,0 Ω/km | Send inquiry |

cross section

max. Ω/km

Other dimensions and colours are possible on request.