With the ongoing industrial networking of production facilities and robotics, the demands on cable design are also increasing. For continuous cabling from the drag chain to the robot arm, the cables must have dynamic properties that conventional drag chain cables cannot meet. That is why specialty cable manufacturer SAB Bröckskes has developed a new low-capacitance cable generation with high bending and torsion resistance.

As a developer and manufacturer of special cables, we have more than 75 years of experience in the design and manufacture of highly flexible cables "Made in Germany." The company launched its first drag chain cable, the S100, 25 years ago. Its successor, the S200 series, has now proven itself in numerous industrial applications for over 20 years and continues to be in high demand due to its high mechanical robustness. With several product innovations and a streamlined product range, we have aligned our standard program of permanently flexible cables with current market developments. The associated reduction in the number of types speeds up the production process by reducing setup times and material changes.

Product innovations for drag chain applications

The polyurethane-coated data cables and drag chain-compatible control cables of the S200 series are considered classics in the SABdynamic portfolio. The series has excellent mechanical properties, is particularly flexible, abrasion-resistant, notch-resistant, oil-resistant, and chemically resistant. The cut-resistant and low-adhesion PUR outer jacket guarantees a long service life and economic efficiency. S200 cables are therefore ideal for continuous use in multi-shift operation with millions of bending cycles and are used, for example, in energy chains, as control or data cables on industrial robots, in production lines, in handling devices, and in automation systems. The S99 ECO is a particularly economical alternative, a cable series with polypropylene core insulation and a polyurethane sheath in a ThinWall design, which is suitable for permanent flexible use with moderate mechanical stress. New to the portfolio is the SABorganic S1000, a climate-friendly cable variant with an outer jacket made of 45% bio-based polyurethane.

Torsion-resistant robot cables

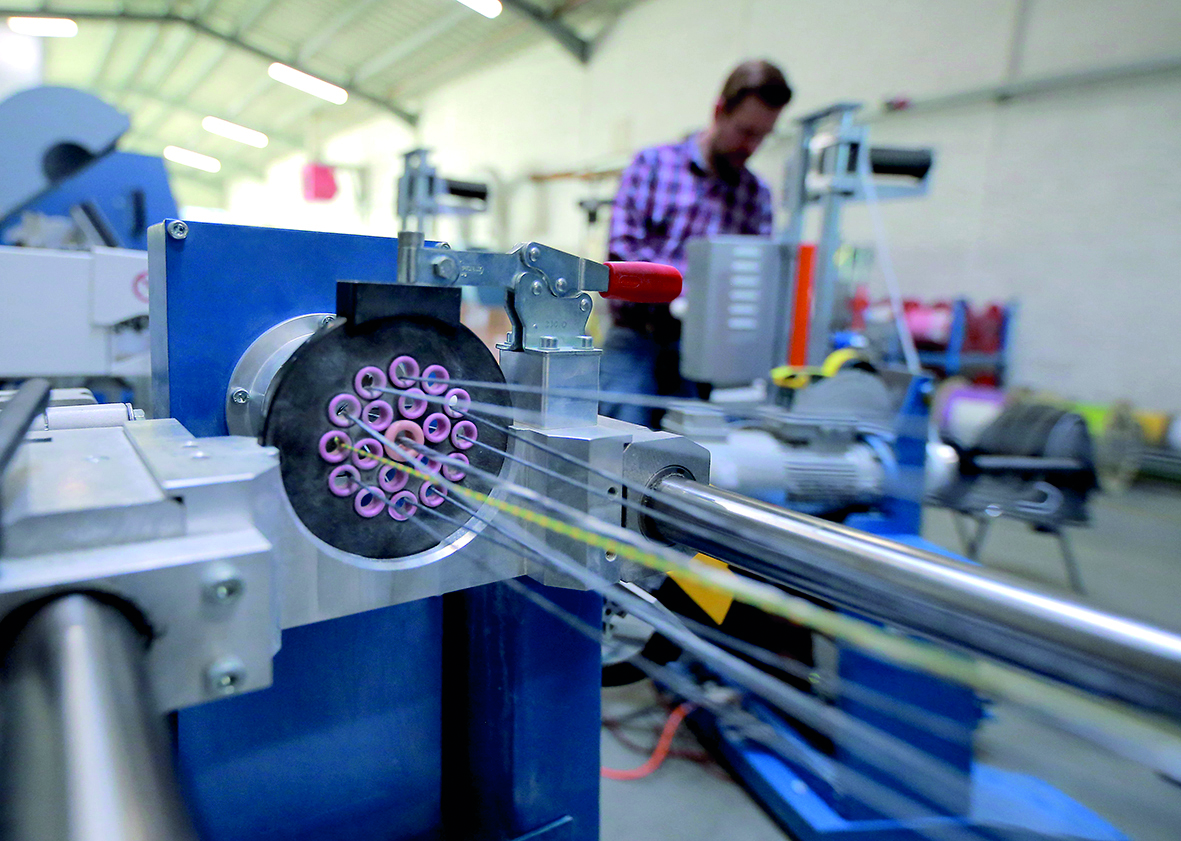

Unlike drag chain cables, permanently flexible control and data cables for industrial robot, plant, and machine tool construction also require outstanding torsion resistance. In addition to frequent bending cycles, the cables must also withstand severe twisting, caused, for example, by the swiveling and rotating movements of production robots. The torsion cables of the RT113, RT113D, RT123, and RT123D series, marketed under the SAB Robot brand, are designed in terms of material, cable design, and stranding for high torsion angles between ± 270° and ± 450° over 0.5 m. The torsion cables withstand mechanical stresses, in particular abrasion and grinding, as well as simultaneous continuous flexible torsion and bending stresses with free movement without tensile stress. They are suitable for dry, damp, and wet locations as well as low ambient temperatures down to -50°C.

New dynamics in cable management

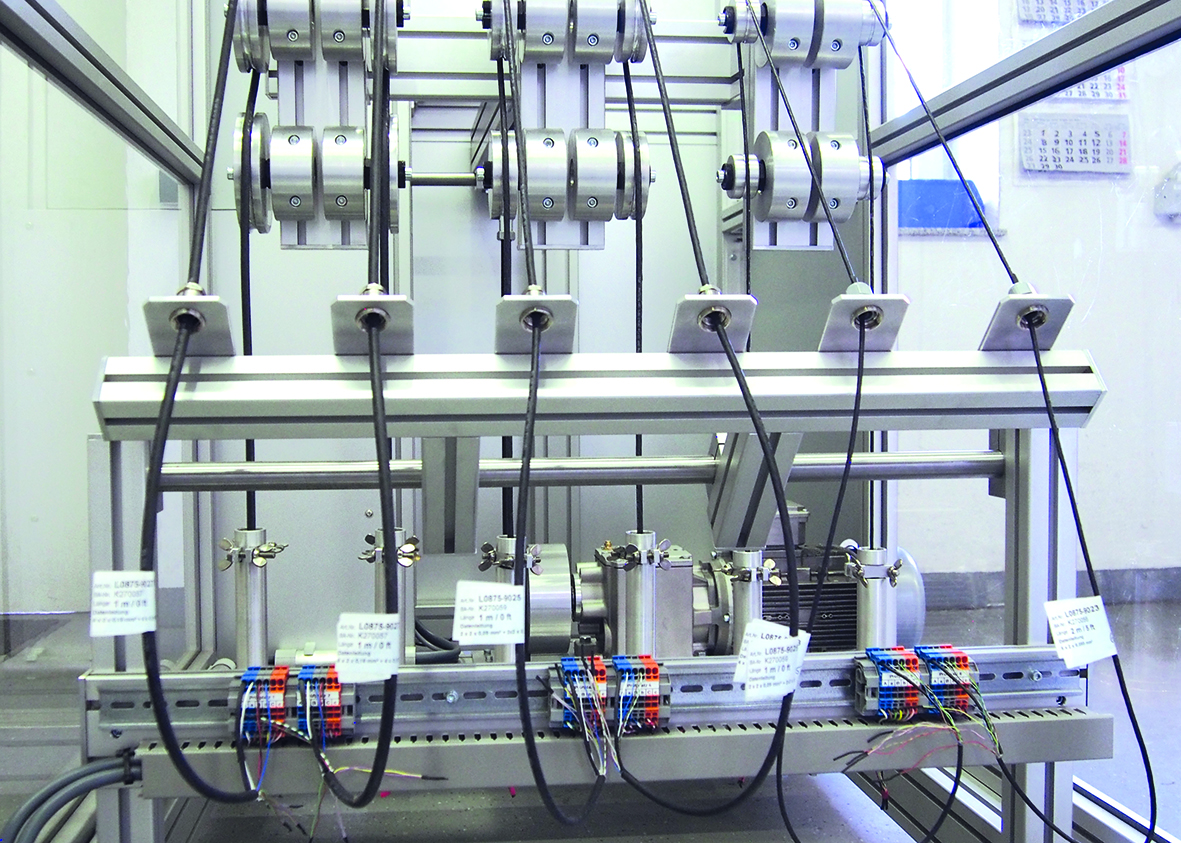

We are now introducing our latest innovation, the new CSA and UL/cUL-approved SABdynamic 900 and 910 cable generation in Control and Data versions. With the 910 series, we are offering a tested standard solution for the first time that can be used in virtually all dynamic applications, from drag chain use to robot cables. The extended range of applications already covers functions that previously required specially designed cables. Combining a highly robust cable design with the tight bending radii and fast bending changes required for drag chains required optimal coordination of material properties and thicknesses from the sheath to the core insulation and stranding. Extensive tests in the SAB test center, which has been expanded with two new testing machines, have confirmed the bending, shearing, and torsion resistance in continuous operation. The special PUR sheath material ensures high robustness of the sheathing even with reduced cable diameters and reduced sheath thickness. Pair or bundle stranding ensures that the cores can withstand millions of bending stresses without distortion or core breakage.

Signal integrity over the entire length

Another advantage of the new cable generation is the reduced line capacity. As the line length increases, capacitive effects intensify, which can lead to unwanted coupling and higher leakage currents. Low-capacitance control cables are therefore particularly advantageous for sensitive control and automation systems. They minimize these undesirable effects and also improve electromagnetic compatibility (EMC). In data cables, the reduced line capacities have a particularly positive effect on signal integrity, which is required for real-time data communication. Thanks to the reduced material thickness of the SABIX-based insulation sheath, the SABdynamic 900 and 910 in the Data version achieve very high signal integrity and therefore guarantee interference-free and loss-free data transmission for real-time applications even with cable lengths exceeding 20 m. In addition, the halogen-free model series has a flame-retardant, self-extinguishing PUR jacket and is therefore also approved for the North American market in accordance with UL and CSA.

Tens of millions of bending and torsion cycles

The type 900 and 910 cables available in the Data and Control versions are designed for voltages up to 350 V and 600 V respectively. Both series can withstand over 10 million bending cycles when installed in a flexible manner and temperatures between -40°C and +90°C. In addition, they have excellent TMPU-tested oil resistance in accordance with EN 50363-10-2 and VDE 0207-363-10-2, as well as good chemical resistance to acids, alkalis, solvents, and hydraulic fluids. They are UV-resistant in accordance with HD 605, ozone-resistant in accordance with DIN EN 50396, saltwater-resistant in accordance with UL 1309, RoHS-compliant, and LABS-critical. In addition, both versions are PFAS-free, which guarantees operational safety for users even in the event of a PFAS ban. We offer the S900 Data as standard in a 12 x 0.14 mm² format as a multi-core unshielded cable and in four multi-pair shielded versions from 4 x 2 x 0.25 mm² to 4 x 2 x 0.75 mm². With the SABdynamic 910 Data and Control model series, we are introducing permanently flexible cables to its range for the first time that are equally suitable for use in drag chains and as robot-compatible torsion cables. Both cable variants withstand over 10 million bending cycles and more than 10 million torsion cycles up to ± 180°/m or 5 million up to ± 360°/m. The Data version of the 910 is available in three standard designs as a multi-core unshielded cable, a multi-pair unshielded cable, and a multi-pair shielded cable. We also offer two multi-core unshielded and two multi-core shielded options as standard control cables. On request, we develop and manufacture special solutions with customer-specific dimensions, different jacket colors, and individual cable designs.

Conclusion

Under the SABdynamic label, we have adapted our range of permanently flexible cables to changing market requirements. In addition to the S200, which has been tried and tested for around 20 years, the S99 ECO, a particularly economical model, and the SABorganic S1000, a more sustainable model with a bio-based outer sheath, have been added to the range. We are now launching the latest generation of its globally deployable data and control cables in the 900 and 910 series. Their particularly low-capacitance cable design ensures high signal integrity for real-time data communication, even over long distances. The robust design and high flexibility enable more than 10 million bending cycles in drag chain applications. Due to its torsion resistance, the robot-compatible SABdynamic 910 is also recommended for continuous cabling from the drag chain to the manufacturing robot.