High demanding requirements in robotics and automation

Highly dynamic motion cycles are now standard in industrial robotics and automation. Robot arms, energy supply systems, and hose assemblies are subject to constant alternating loads, with torsion in particular posing one of the greatest mechanical challenges for electrical cables. Specially designed torsion cables are required to prevent failures, signal interference, or premature wear.

RT 123: Designed for continuous torsional stress

The RT 123 from SAB Bröckskes was developed precisely for such application scenarios. It is designed for use in highly mobile, torsionally stressed applications such as robot arms, hose packages, and energy supply systems with rotational stress. With a design for torsion angles of up to ± 450° per 0.5 m, the cable is particularly suitable for applications with repeated, uniform rotational movements, as are typical in robotics.

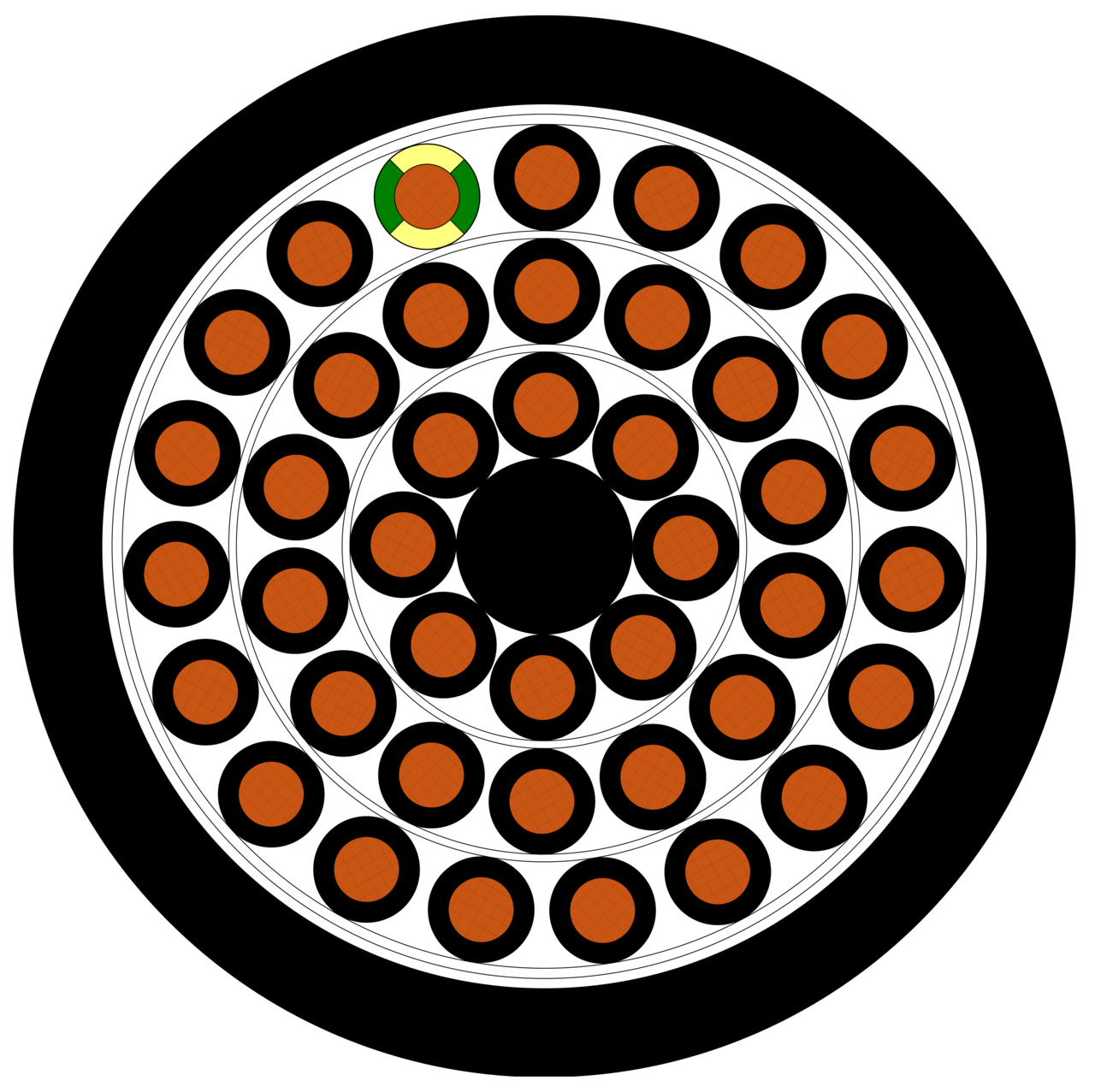

A key design feature of the RT 123 is its highly flexible structure, which ensures reliable opera-tion even with tight bending radii and complex movement sequences. This is based, among other things, on the fine-wire copper conductor (from 0.50 mm² according to IEC 60228, class 6) in combination with specially coordinated stranding. Mesh tape layers between the stranding layers and an additional fleece under the outer sheath ensure even distribution of mechanical loads and contribute to the high service life of the cable under torsion and bending stress.

TPE is used for wire insulation, while the halogen-free PUR outer jacket (TMPU) offers high resistance to abrasion, oils, chemicals, and UV radiation. At the same time, the cable remains flexible even in continuous use; the minimum bending radius is 12 × d.

In addition to its mechanical design, the RT 123 meets relevant normative requirements and is UL and CSA certified (including UL AWM Style 21060, up to 600 V). This makes it suitable for internationally oriented machine and system concepts. It also meets requirements for halogen-free, flame-retardant, RoHS compliance, and is PFAS-free.

Typical areas of application include packaging, tool, wood, textile, welding, and cutting equipment manufacturing. In addition, the RT 123 is used in robot systems where cables within energy chains or robot arms are subject to constant torsion and bending stress. The wide range of conductor numbers and cross-sections allows flexible adaptation to different power and signal requirements.

Technical features and product advantages at a glance

- Designed for torsional loads of up to ± 450° per 0.5 m

- High flexibility for tight bending radii and complex movement profiles

- Abrasion-resistant, halogen-free PUR outer sheath

- Resistant to oils, chemicals, and UV radiation

- UL and CSA certified for international use

Advanced solutions for robot-compatible applications

In addition to the RT 123, SAB Bröckskes offers a wide range of robot-compatible cables for various mechanical and electrical requirements. This also includes customized solutions for complex movement profiles, special environmental conditions, or international standards.