From copper wire to finished connection cable

Einblicke in die moderne Kabelproduktion

The production of high-quality specialty cables is a precise, multi-stage process in which state-of-the-art machinery, extensive experience, and premium materials work together. From the initial drawing of ultra-fine copper wires, through insulation and stranding, to jacket extrusion and final assembly, a reliable cable is created step by step, perfectly tailored to its intended application. The following overview clearly illustrates how various raw materials are transformed into a technically sophisticated cable – robust, high-performance, and ready for use in industry, mechanical engineering, or demanding custom applications.

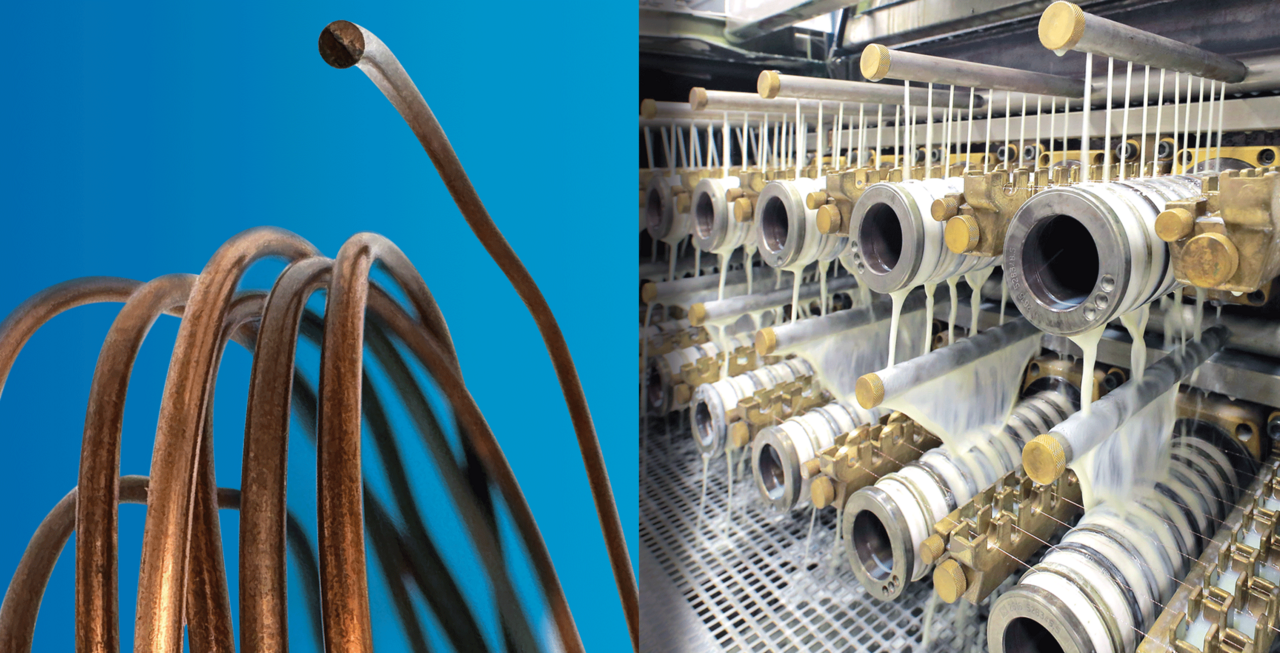

1 Wire Drawing – From Raw Material to Fine Conductor Wire

Before a cable can be produced, copper is drawn through several highly precise drawing dies made of exceptionally durable materials such as natural or industrial diamond. By gradually reducing the diameter, extremely fine wires are produced. A cooling and lubricating emulsion protects the wire during the drawing process, while subsequent recrystallization annealing restores its flexibility. This process creates ultra-fine individual wires – the foundation of all flexible cables.

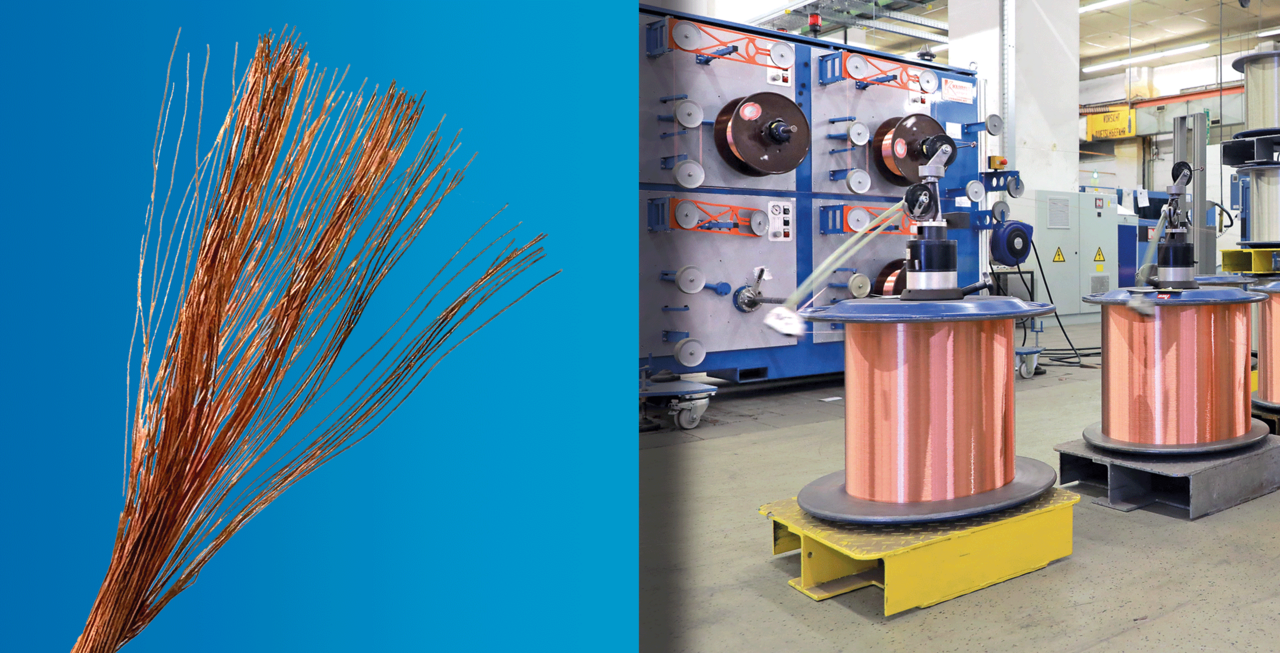

2 Stranding – From Single Wires to a Flexible Conductor

To produce flexible or high-load cables, multiple individual wires are stranded together. A concentric structure is particularly common: a central wire is evenly wrapped with several layers of additional wires. The lay length determines how flexible the stranded conductor will be.

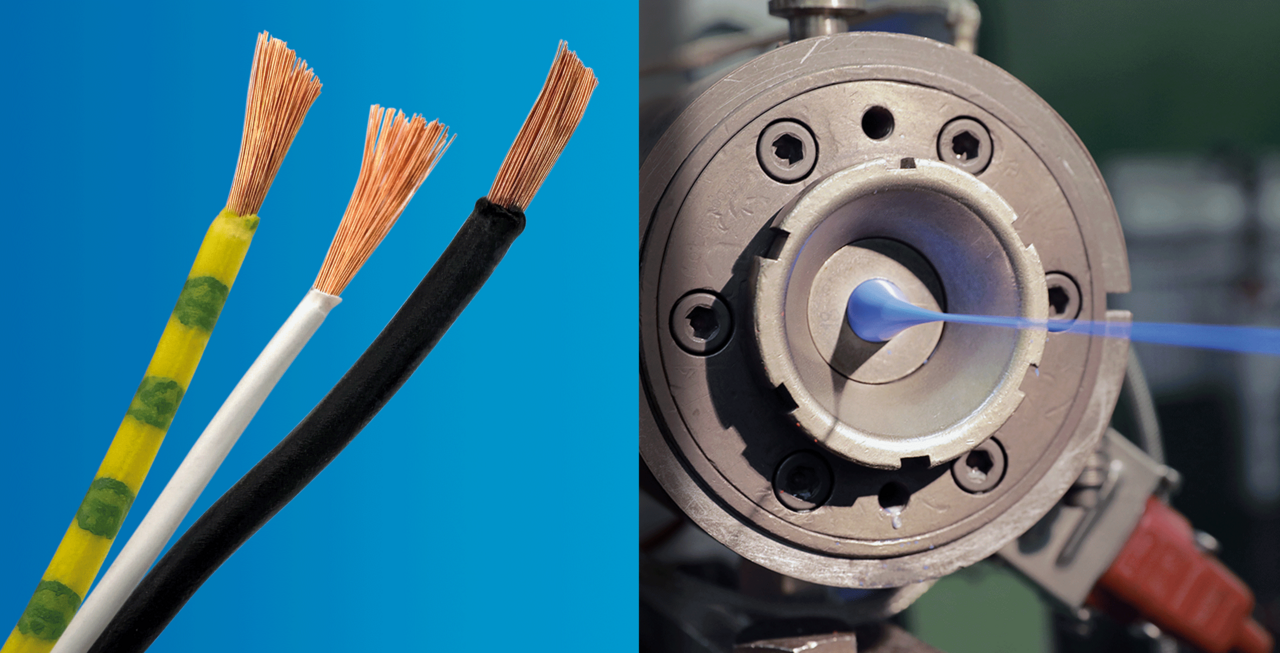

3 Conductor Insulation – Protection and Electrical Separation

The next step is insulating the conductor. A suitable thermoplastic – e.g., PVC, PE, PP, or XLPE – is melted in an extruder and applied evenly around the conductor. The insulated wire is then cooled in a water bath, giving it mechanical stability. Colors or numbers are added to ensure safe identification in the final cable cross-section.

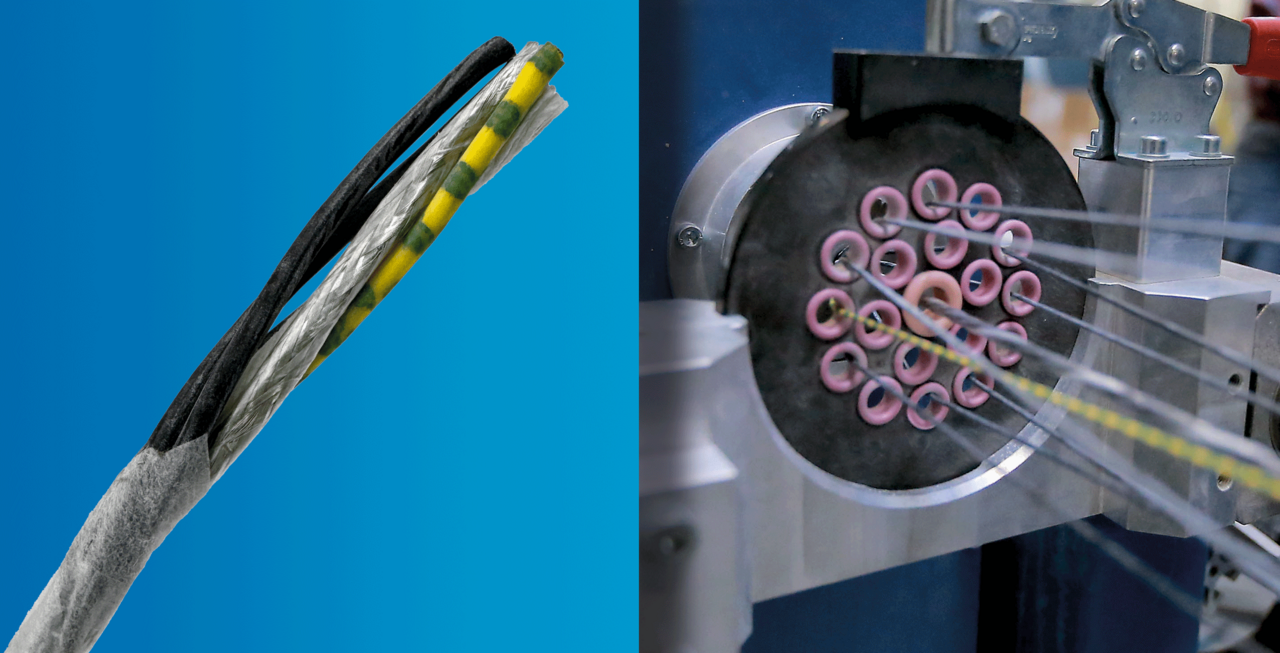

4 Twisting – Constructing Multi-Core Cables

The insulated conductors are now combined into multi-core cables and twisted together at defined lay lengths to optimize electrical and mechanical properties. For dynamic applications, such as in drag chains, a special counter-twisting process is often used to reduce torsional stress in the cable. Filler elements ensure a stable, round cable geometry.

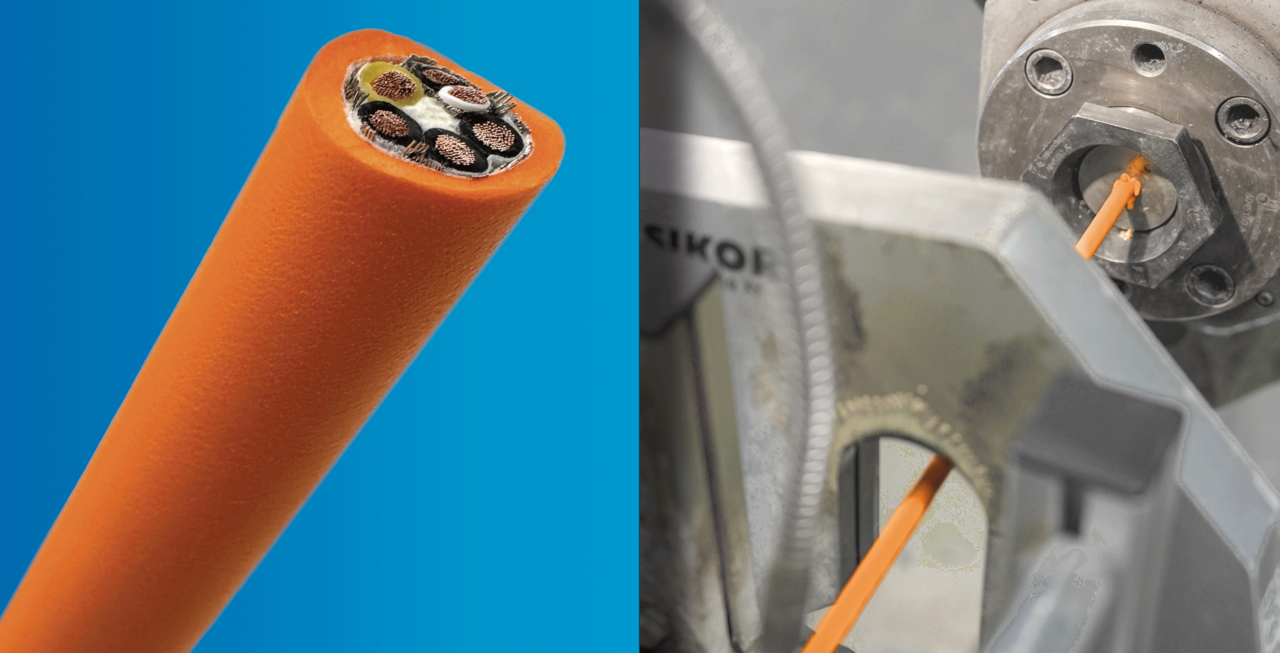

6 Jacket Extrusion – Outer Protection of the Cable

In this step, the cable receives its outer jacket. It is extruded from durable plastics such as PVC, PUR, or TPE, protecting the internal components from moisture, abrasion, oils, and chemical influences. Modern measuring systems monitor wall thickness, diameter, and surface quality during extrusion. Finally, the finished cable is wound onto reels or coils.

7 Cable Assembly – From Finished Cable to Ready-to-Use Plug-and-Play Solution

In the final production step, the extruded and tested cable is processed into a ready-to-use assembly. The cable is cut to length, stripped, the conductors are prepared, and if required, fitted with ferrules. The desired connector is then attached – using screw, crimp, or solder connections, up to fully molded systems. Modern crimping and testing equipment ensures electrical and mechanical reliability. After functional and tensile testing, the assembled cable is labeled, packaged, and immediately ready for use – precisely according to customer specifications.