The trouble-free and long service life of reeling cables requires the adherence to certain installation guidelines.

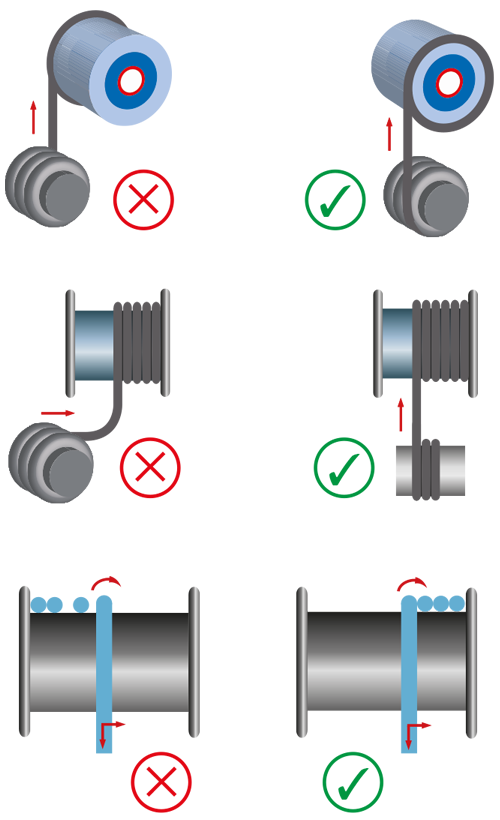

1. Reeling the cable

The cable shall be wound directly from the supplied drum to the reeling drum. The complete unwinding of the cable isn’ t necessary. A straight torsion-free guiding has to be observed. Equally the cable has to be fixed and connected torsion-free. The indicated min. bending radius has to be adhered to.

4. Stranding direction of the cable

The start of winding of reeling cables on cylinder drums shall be made in stranding direction. Cables with right stranding direction (Z-lay) shall be operated to the right side and vice versa. If the stranding direction isn’t known, please contact our technical support for any information.

5. Tensile load limit values

Without special notice in our catalogue, the tensile stress of the copper conductors shall not exceed 15 N/mm² (DIN VDE 0298-3). In case of higher tensile stress, we recommend to contact our technical support to align the cable construction to the requirements. The max. allowed limit deviations of the tensile stress are to be understood as the sum of the static and dynamic stress.

Maintenance notes

To ensure the longevity of the cable, maintenance is required at least once a month, depending on use. The pipe should be fully laid out on the following steps carried out:

- turn back any axial twists in the cable

- visually check the cable for damage

- check roller packs for free movement

- check the connection side

Do you have any questions about our products? Your direct line to our experts! Contact