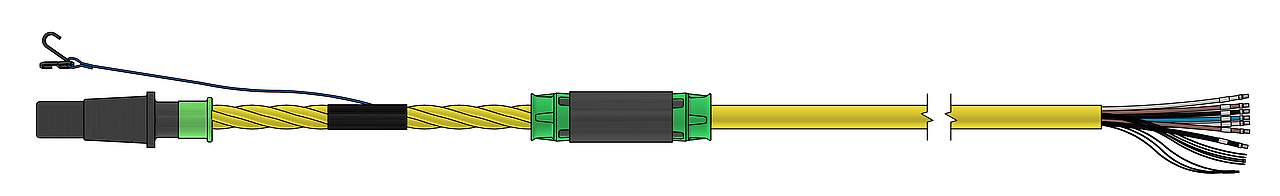

>> Individual configuration of reeling connection cables with connectors <<

Your cable combination is not yet shown in our catalogue 400Hz and 28V DC? No problem! Using the following sample configuration, you can easily configure your individual combination of cable and the required connectors yourself. We will be happy to advise you. Just contact us directly.

Side 2

☐ wire end sleeves _________________________

☐ pin terminals _________________________

☐ ring cable lugs _________________________

Further accessories

| ☐ with 90% Switch | ☐ PIN E | ☐ PIN F | ☐ PIN E+F |

| ☐ push buttons | ☐ red | ☐ green | ☐ black |

| ☐ LED | ☐ red | ☐ green | ☐ yellow |

| ☐ thermocouple | ☐ PT100 | ☐ PTC120 | ☐ PTC100 |

| ☐ with strain relief | _________________________ mm behind connector end | ||

Note on processing of cable L3400-0228 & L3400-0251

In the centre of the blue wire (neutral conductor) is a core element. This must be removed a short distance before installation in the area of the connection points or cable lugs, as it must not be assembled.

Caution: The aramid thread in the core element must not be removed or connected over the entire length of the cable.

Procedure: Carefully expose the stranded wire, fan it out carefully and remove the core element without damaging the wires of the stranded wire. Then reshape the stranded wire and install the cable lug or similar in accordance with the manufacturer‘s instructions.

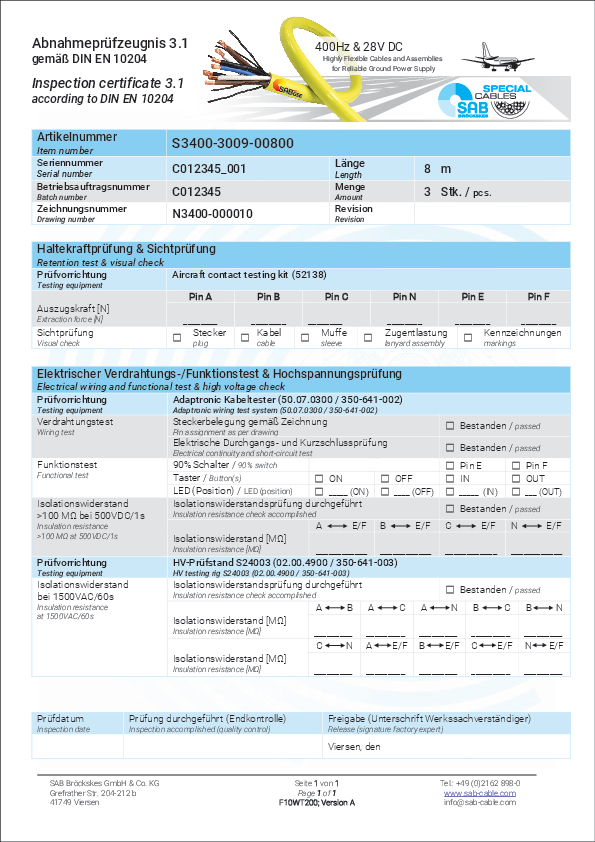

Inspection certificate 3.1

An acceptance test certificate 3.1 (DIN EN 10204) is issued as standard for all assembled 400 Hz and 28 V DC cables. It documents the quality and safety tests and serves as proof of traceability. Each product is also marked separately to ensure clear identification and traceability.

Core tests:

- Insulation resistance at 500 V DC / 1 s (≥ 1 MΩ)

- High-voltage test at bei 2000 V DC / 60 s

For further tests, please refer to the sample acceptance test certificate: