Application

Our GP 270 V DC cable in 8 × 8 AWG + 8 × 8 AWG + 2 × 3 × 14 AWG is specifically designed for the ground power supply of F‑35 fighter jets and ensures reliable energy delivery to the aircraft systems. Its dual-jacket design with a red inner and yellow outer jacket provides a clear abrasion indicator, facilitates replacement planning, and enhances the safety of ground personnel. The cable meets the highest requirements for mechanical strength, chemical resistance, hydrolysis and microbial resistance, is halogen-free, and withstands extreme temperature ranges from -50 °C to +110 °C.

With minimal voltage drop (DC resistance max. 7.98 Ω/km for 2.5 mm²) and test voltages of 3–5.5 kV AC, it guarantees safe operation even under extreme conditions. Thus, our GP 270 V DC cable offers a durable, low-maintenance, and highly reliable solution for the demanding ground power supply of modern military aircraft.

Outstanding features

- low capacity insulation

- abrasion-resistant PUR sheath

- cold flexible

- halogen-free

- oil resistant

- weather resistant

- with wear indicator

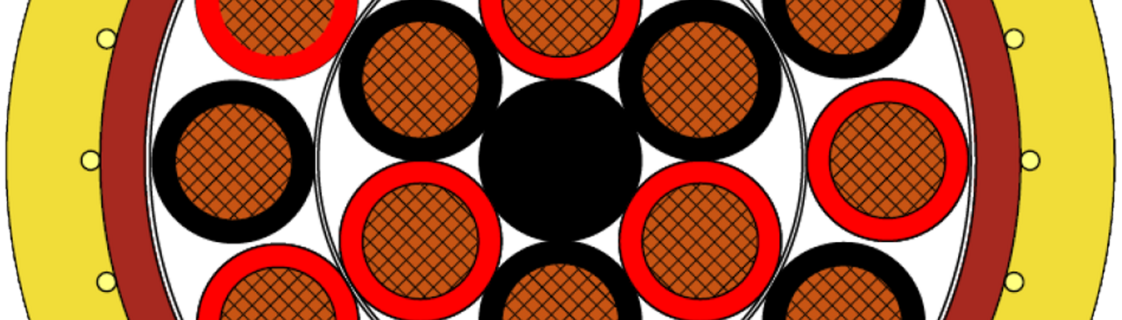

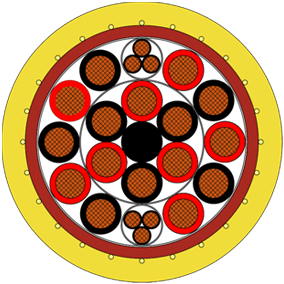

Construction

| Conductor | bare copper strands |

|---|---|

| Insulation | SABIX® |

| Colour code | 14 AWG: black with numbers 8 AWG: red and black with numbers |

| Stranding | 14 AWG: cores twisted triplewise, wrapped with tape 8 AWG: twisted in layers, wrapped with tape |

| Overall stranding | 14 AWG: elements and cores in layers 8 AWG: element in centre, wrapped with tape |

| Inner sheath | PUR, red |

| Supporting braid | aramid |

| Outer sheath | PUR, yellow |

bare copper strands

SABIX®

14 AWG: black with numbers

8 AWG: red and black with numbers

14 AWG: cores twisted triplewise, wrapped with tape

8 AWG: twisted in layers, wrapped with tape

14 AWG: elements and cores in layers

8 AWG: element in centre, wrapped with tape

PUR, red

aramid

PUR, yellow

Technical Data

| Nominal voltage | 270 V (DC) |

|---|---|

| Testing voltage | 14 AWG: core/core 3000 V (AC) 5 min. 8 AWG: core/core 5500 V (AC) 5 min. |

| Minimum bending radius | fixed laying: 4 x d free movement: 6 x d |

| Temperature range | fixed laying: -50°C/+90°C flexible use: -40°C/+90°C limited time of use: +110°C (up to 7500h) |

| Halogen free | acc. to IEC 60754-1 |

| Fire performance | sheath material: UL 94 V2 |

| Chemical resistance | good against acids, alkalines, solvents, hydraulic liquids etc. |

| Hydrolysis- and microbe resistance | very good - acc. to EN 50363-10-2 |

| Salt water resistance | very good - acc. to UL 1309 |

| Oil resistance | very good - acc. to EN 50363-10-2 |

| MUD resistance | very good - acc. to IEC 60092-360 |

| Weather resistance | very good - acc. to HD 605 (VDE 0276-605) |

| Ozone resistance | very good - acc. to EN 50396 |

| Mechanical strength | properties of PUR-outer jacket: - high tensile strength - high tear strength - high abrasion resistance - high notch resistance - high shear strength |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

270 V (DC)

14 AWG: core/core 3000 V (AC) 5 min.

8 AWG: core/core 5500 V (AC) 5 min.

fixed laying: 4 x d

free movement: 6 x d

fixed laying: -50°C/+90°C

flexible use: -40°C/+90°C

limited time of use: +110°C (up to 7500h)

acc. to IEC 60754-1

sheath material: UL 94 V2

good against acids, alkalines, solvents, hydraulic liquids etc.

very good - acc. to EN 50363-10-2

very good - acc. to UL 1309

very good - acc. to EN 50363-10-2

very good - acc. to IEC 60092-360

very good - acc. to HD 605 (VDE 0276-605)

very good - acc. to EN 50396

properties of PUR-outer jacket:

- high tensile strength

- high tear strength

- high abrasion resistance

- high notch resistance

- high shear strength

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section | Outer-ø | Copper figure | Cable weight ≈ |

Ohmic resistance at 20°C max. | |

|---|---|---|---|---|---|---|

| L34000503 | 8 x 8 AWG + 8 x 8 AWG + 2 x 3 x 14 AWG | min. 40,0 mm - max. 41,9 mm | 1680 kg/km | 2564 kg/km | 8 AWG: 1,91 Ω/km | 10 AWG: 7,98 Ω/km | Send inquiry |

cross section

at 20°C max.

Other dimensions and colours are possible on request.