Application

For flexible use on GPUs.

Outstanding features

- low capacity insulation

- very flexible and smooth handling

- very good installation in narrowest spaces

- good resistance

- low wear

- with wear indicator

Additional information

Alternative construction for 2 x (120,0 mm² + 4 x 1,0 mm²) or 4 x (70,0 mm² + 4 x 1,0 mm²) as all-in-one cable solution.

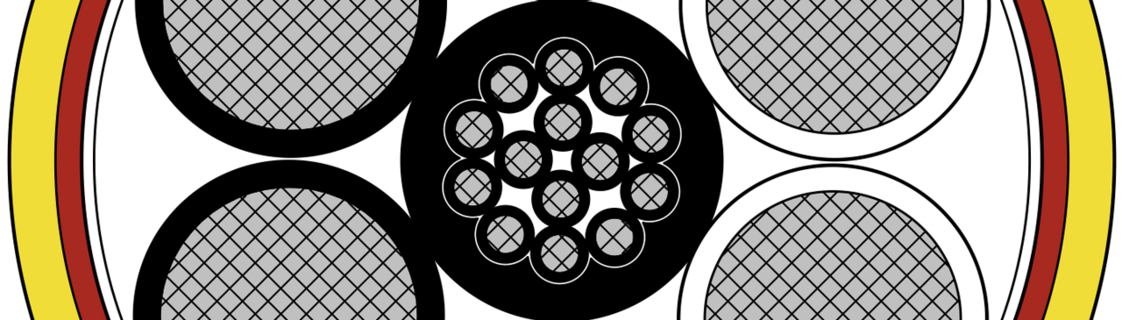

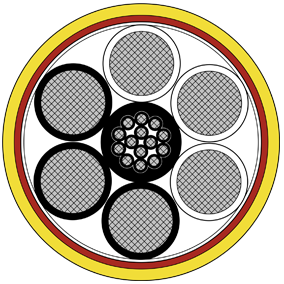

Construction

| Conductor | tinned copper strands, fine wires acc. to IEC 60228 class 5 |

|---|---|

| Insulation | SABIX® |

| Colour code | 1,0 mm²: black cores with numbers 1 - 14 40,0 mm²: black cores with numbers 1 – 3, white cores with numbers 1 - 3 |

| Stranding | 1,0 mm²: cores optimized stranded in layers |

| Inner sheath | special polymer, black |

| Stranding | core 40,0 mm² optimized stranded in layers, element (14 x 1,0 mm²) in the centre, wrapped with overlapping non-woven tape |

| Inner sheath | special polymer, red |

| Outer sheath | special polymer, yellow |

tinned copper strands, fine wires acc. to IEC 60228 class 5

SABIX®

1,0 mm²: black cores with numbers 1 - 14

40,0 mm²: black cores with numbers 1 – 3, white cores with numbers 1 - 3

1,0 mm²: cores optimized stranded in layers

special polymer, black

core 40,0 mm² optimized stranded in layers,

element (14 x 1,0 mm²) in the centre,

wrapped with overlapping non-woven tape

special polymer, red

special polymer, yellow

Technical Data

| Nominal voltage | Uo/U 28 V DC |

|---|---|

| Testing voltage | core/core 600 V AC/DC 50 Hz |

| Min. bending radius | fixed laying: 4 x d flexible application: 6 x d |

| Temperature range | fixed laying: -40/+70 °C flexible application: -30/+70 °C |

| Fire performance | acc. to IEC 60332-1-2 |

| Chemical resistance | good against acids, alkalines, solvents, hydraulic liquids, etc. |

| Hydrolysis and microbial resistance | good |

| Salt water resistance | good |

| Oil resistance: | good - acc. to EN 50290-2-22 |

| Weather resistance | good |

| Ozone resistance | good |

| Abrasion | acc. to UL 2556-2021 and JIS C3005 |

| Fuel resistant | petrol, diesel and kerosene (Jet A-1) |

| Mechanical resistance | characteristics of the outer sheath: - high tensile strength - high tear strength - high abrasion resistance - high notch resistance - high shear strength |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

Uo/U 28 V DC

core/core 600 V AC/DC 50 Hz

fixed laying: 4 x d

flexible application: 6 x d

fixed laying: -40/+70 °C

flexible application: -30/+70 °C

acc. to IEC 60332-1-2

good against acids, alkalines, solvents, hydraulic liquids, etc.

good

good

good - acc. to EN 50290-2-22

good

good

acc. to UL 2556-2021 and JIS C3005

petrol, diesel and kerosene (Jet A-1)

characteristics of the outer sheath:

- high tensile strength

- high tear strength

- high abrasion resistance

- high notch resistance

- high shear strength

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section | Outer-ø | Copper figure | Cable weight ≈ |

Ohmic resistance max. Ω/km | |

|---|---|---|---|---|---|---|

| L34000300 | 6 x 40,0 mm² + 14 x 1,0 mm² | min. 38,0 mm - max. 39,8 mm | 2438 kg/km | 3112 kg/km | 40,0 mm²: 0,50 Ω/km | 1,0 mm²: 20,0 Ω/km | Send inquiry |

cross section

max. Ω/km

Other dimensions and colours are possible on request.