Application

For use in flexible applications, e.g. on mobile GPUs, PIT systems and as a connecting cable between sleeve and plug in reeling applications.

Outstanding features

- low capacity insulation

- more flexible than polyurethane cables

- cold flexible

- oil resistant

- with wear indicator

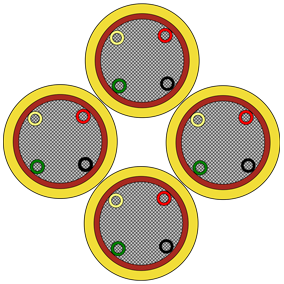

Construction

| Conductor | tinned copper strands, fine wires acc. to IEC 60228 class 5 |

|---|---|

| Insulation | SABIX® |

| Colour code | control cores: red, black, green, yellow power supply cores: red |

| Stranding | control cores within the power supply core |

| Inner sheath | SABIX®, red |

| Outer sheath | special polymer, yellow |

tinned copper strands, fine wires acc. to IEC 60228 class 5

SABIX®

control cores: red, black, green, yellow

power supply cores: red

control cores within the power supply core

SABIX®, red

special polymer, yellow

Technical Data

| Nominal voltage | Uo/U 115/200 V |

|---|---|

| Max. permissible operating voltage | Uo/U 0,6/1 kV |

| Testing voltage | core/core 4000 V AC 50 Hz |

| Min. bending radius | fixed laying: 4 x d flexible application: 6 x d |

| Temperature range | fixed laying: -40/+70 °C flexible application: -30/+70 °C |

| Fire performance | acc. to IEC 60332-1-2 |

| Oil resistance | good - acc. to EN 50290-2-22 |

| Chemical resistance | good against acids, alkalines, solvents, hydraulic liquids, etc. |

| Weather resistance | good |

| Salt water resistance | good |

| Hydrolysis and microbial resistance | good |

| Ozone resistance | good |

| Abrasion | acc. to UL 2556-2021 and JIS C3005 |

| Fuel resistant | petrol, diesel and kerosene (Jet A-1) |

| Mechanical resistance | characteristics of the outer sheath: - good tensile strength - good abrasion resistance - good notch resistance |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

Uo/U 115/200 V

Uo/U 0,6/1 kV

core/core 4000 V AC 50 Hz

fixed laying: 4 x d

flexible application: 6 x d

fixed laying: -40/+70 °C

flexible application: -30/+70 °C

acc. to IEC 60332-1-2

good - acc. to EN 50290-2-22

good against acids, alkalines, solvents, hydraulic liquids, etc.

good

good

good

good

acc. to UL 2556-2021 and JIS C3005

petrol, diesel and kerosene (Jet A-1)

characteristics of the outer sheath:

- good tensile strength

- good abrasion resistance

- good notch resistance

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section | Outer-ø | Copper figure | Cable weight ≈ |

Ohmic resistance max. Ω/km | |

|---|---|---|---|---|---|---|

| L34000001 | 4 x (50,0 mm² + 4 x 1,0 mm²) | max. 39,9 mm (Ader min. 16 mm - max. 16,6mm) | 2096,0 kg/km | 2436 kg/km | 50,0 mm²: 0,393 Ω/km | 1,0 mm²: 20,0 Ω/km | Send inquiry |

| L34000002 | 4 x (70,0 mm² + 4 x 1,0 mm²) | ca. 42,5 mm (Ader max. 17,9 mm) | 2957,0 kg/km | 3174 kg/km | 70,0 mm²: 0,277 Ω/km | 1,0 mm²: 20,0 Ω/km | Send inquiry |

cross section

max. Ω/km

Other dimensions and colours are possible on request.