Application

GP 400 SF DR – 400 Hz Reeling Cable for Motorized Cable Reels and Scissor Systems

The GP 400 SF DR is a highly flexible 400 Hz reeling cable with 7 power conductors of 35.0 mm² and 6 x 4 x 1.0 mm², developed for dynamic use on motorized cable reels - starting from a minimum drum core diameter of just 600 mm as well as in scissor systems at passenger boarding bridges or airport ground power systems. Its symmetrical structure and rugged design make it ideal for frequent winding and unwinding under continuous movement. The durable PUR outer sheath is abrasion-resistant, oil- and fuel-resistant, weatherproof and UV-stable, making it suitable for demanding outdoor environments. The cable is also halogen-free, cold flexible down to -40 °C, and complies with IEC 60332-3-24 for flame retardancy. Integrated aramid strain relief ensures mechanical durability even under high tensile loads. With a nominal voltage of 0.6/1 kV and a test voltage of 4000 V AC, it guarantees reliable 400 Hz power transmission. For fast and secure integration, the GP 400 SF DR is also available as a fully pre-assembled Plug’n’Play solution from SAB Bröckskes, including connectors and ready-to-use terminations - everything from a single source. This makes it the ideal choice for operators seeking maximum flexibility, safety, and efficiency.

Outstanding features

- low capacity insulation

- abrasion-resistant PUR jacket

- cold flexible

- oil resistant

- weather resistant

- with wear indicator

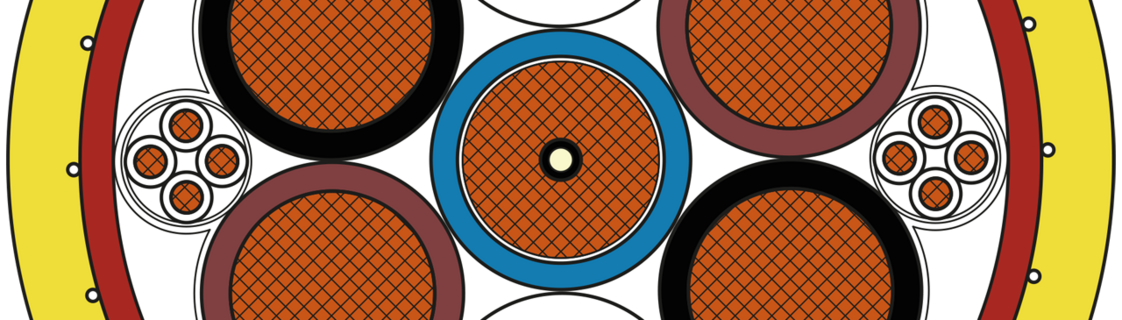

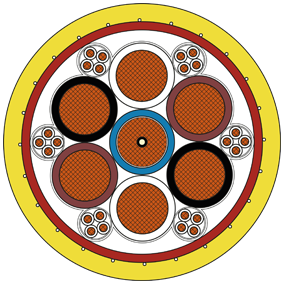

Construction

| Conductor | bare copper strands, fine wires acc. to IEC 60228 class 5 |

|---|---|

| Insulation | SABIX® |

| Colour code | 1,0 mm²: white cores with numbers 1 - 24 35,0 mm²: blue, 2 x white, 2 x brown, 2 x black |

| Stranding | 1,0 mm²: cores twisted as quad, wrapped with overlapping foil 35,0 mm²: cores wrapped with overlapping foil. All elements optimized stranded in layers, wrapped with overlapping non-woven tape |

| Inner Sheath | PUR, red |

| Supporting screen | aramid |

| Outer sheath | PUR, yellow |

bare copper strands, fine wires acc. to IEC 60228 class 5

SABIX®

1,0 mm²: white cores with numbers 1 - 24

35,0 mm²: blue, 2 x white, 2 x brown, 2 x black

1,0 mm²: cores twisted as quad, wrapped with overlapping foil

35,0 mm²: cores wrapped with overlapping foil.

All elements optimized stranded in layers, wrapped with overlapping non-woven tape

PUR, red

aramid

PUR, yellow

Technical Data

| Nominal voltage | Uo/U 115/200 V |

|---|---|

| Max. permissible operating voltage | Uo/U 0,6/1 kV |

| Testing voltage | core/core 4000 V AC 50 Hz |

| Min. bending radius | fixed laying: 4 x d flexible application: 6 x d for repeated winding action guided on pulleys: 7,5 x d drum: min. 600 mm inner diameter |

| Min. tensile strength | 4035 N (15 N/mm²) |

| Temperature range | fixed laying: -50/+90 °C flexible application: -40/+90 °C |

| Fire performance | sheath material: UL 94 V2 |

| Oil resistance | very good - acc. to EN 50363-10-2 |

| Chemical resistance | good against acids, alkalines, solvents, hydraulic liquids, etc |

| Weather resistance: | very good - acc. to HD 605 (VDE 0276-605) |

| Ozone resistance | very good - acc. to EN 50396 |

| Salt water resistance | very good - acc. to UL 1309 |

| MUD resistance | very good - acc. to IEC 60092-360 |

| Hydrolysis and microbial resistance | very good - acc. to EN 50363-10-2 |

| Abrasion | acc. to UL 2556-2021 and JIS C3005 |

| Fuel resistant | petrol, diesel and kerosene (Jet A-1) |

| Mechanical resistance | characteristics of the outer sheath: - very high tensile strength - very high tear strength - very high abrasion resistance - very high notch resistance - very high shear strength |

| Absence of harmful substances | gemäß RoHS-Richtlinie der Europäischen Union |

Uo/U 115/200 V

Uo/U 0,6/1 kV

core/core 4000 V AC 50 Hz

fixed laying: 4 x d

flexible application: 6 x d for repeated winding action

guided on pulleys: 7,5 x d

drum: min. 600 mm inner diameter

4035 N (15 N/mm²)

fixed laying: -50/+90 °C

flexible application: -40/+90 °C

sheath material: UL 94 V2

very good - acc. to EN 50363-10-2

good against acids, alkalines, solvents, hydraulic liquids, etc

very good - acc. to HD 605 (VDE 0276-605)

very good - acc. to EN 50396

very good - acc. to UL 1309

very good - acc. to IEC 60092-360

very good - acc. to EN 50363-10-2

acc. to UL 2556-2021 and JIS C3005

petrol, diesel and kerosene (Jet A-1)

characteristics of the outer sheath:

- very high tensile strength

- very high tear strength

- very high abrasion resistance

- very high notch resistance

- very high shear strength

gemäß RoHS-Richtlinie der Europäischen Union

Dimensions

| item no. |

No. of cores x cross section | Outer-ø | Copper figure | Cable weight ≈ |

Ohmic resistance max. Ω/km | |

|---|---|---|---|---|---|---|

| L34000228 | 7 x 35,0 mm² + 6 x 4 x 1,0 mm² | ca. 42,3 mm - max. 42,9 mm | 2592 kg/km | 3374 kg/km | 35,0 mm²: 0,55 Ω/km | 1,0 mm²: 19,5 Ω/km | Send inquiry |

cross section

max. Ω/km

Other dimensions and colours are possible on request.