Application

CC 600 CP is a PUR control cable with numbered cores and overall copper screen. Moreover, it is notch and oil resistant. Additionally, it has a good chemical resistance. Due to the PUR outer sheath the cable is recommended for machine and industrial plant construction, material handling techniques, car manufacturing industry, handling and automation technologies, iron, steel, and chemical industries.

Outstanding features

- UL recognized, CSA approved

- oil resistant

- abrasion resistant

- notch resistant

- good chemical resistance

- PFAS-free

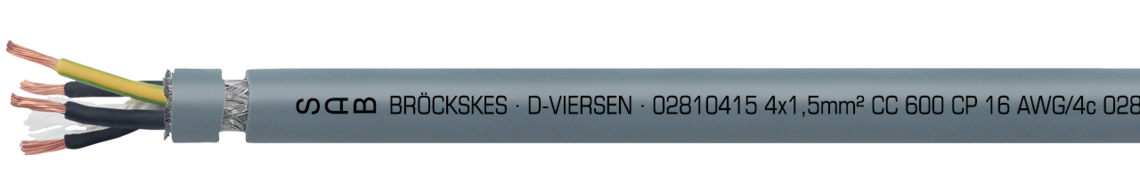

Construction

| Conductor | bare copper strands acc. to IEC 60228, VDE 0295, class 5 |

|---|---|

| Insulation | PVC, TI2 acc. to EN 50363-3 + VDE 0207-363-3 |

| Colour code | black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334, green-yellow earth wire from 3 cores |

| Stranding | in layers |

| Wrapping | PETP foil |

| Screen | tinned copper braiding |

| Wrapping | non-woven tape |

| Sheath material | PU acc. to UL 758 |

| Sheath colour | grey (RAL 7000) |

bare copper strands acc. to IEC 60228, VDE 0295, class 5

PVC, TI2 acc. to EN 50363-3 + VDE 0207-363-3

black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334, green-yellow earth wire from 3 cores

in layers

PETP foil

tinned copper braiding

non-woven tape

PU acc. to UL 758

grey (RAL 7000)

Technical data

| Nominal voltage | Uo/U: 300/500 V UL/CSA: 600 V |

|---|---|

| Testing voltage | core/core 2000 V core/screen 2000 V |

| Min. bending radius | fixed laying: 5 x d flexible application: 10 x d |

| Radiation resistance | 5 x 10^7 cJ/kg |

| Temperature range | DIN VDE fixed laying: -40/+70°C DIN VDE flexible application: +5/+70°C UL/CSA: up to +80°C |

| Fire performance | flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2, |

| Oil resistance | very good - oilrating 60°C acc. to UL 1581 |

| Chem. resistance | good against acids, alkalines, solvents, hydraulic liquids, etc. |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

Uo/U: 300/500 V

UL/CSA: 600 V

core/core 2000 V

core/screen 2000 V

fixed laying: 5 x d

flexible application: 10 x d

5 x 10^7 cJ/kg

DIN VDE fixed laying: -40/+70°C

DIN VDE flexible application: +5/+70°C

UL/CSA: up to +80°C

flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2,

UL VW-1, CSA FT1, FT2

very good - oilrating 60°C acc. to UL 1581

good against acids, alkalines, solvents, hydraulic liquids, etc.

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section |

Largest single wire-ø | Copper figure | Cable weight ≈ |

Outer-ø ± 10% | |

|---|---|---|---|---|---|---|

| L02810205 | 2 x 0,50 mm² | 0,21 mm | 26,1 kg/km | 62 kg/km | 6,7 mm | Send inquiry |

| L02810305 | 3 x 0,50 mm² | 0,21 mm | 31,3 kg/km | 70 kg/km | 7 mm | Send inquiry |

| L02810405 | 4 x 0,50 mm² | 0,21 mm | 38,1 kg/km | 80 kg/km | 7,4 mm | Send inquiry |

| L02810505 | 5 x 0,50 mm² | 0,21 mm | 45,2 kg/km | 95 kg/km | 8 mm | Send inquiry |

| L02810705 | 7 x 0,50 mm² | 0,21 mm | 57,5 kg/km | 112 kg/km | 8,5 mm | Send inquiry |

| L02811205 | 12 x 0,50 mm² | 0,21 mm | 90,6 kg/km | 167 kg/km | 10,6 mm | Send inquiry |

| L02811805 | 18 x 0,50 mm² | 0,21 mm | 146,4 kg/km | 245 kg/km | 12,4 mm | Send inquiry |

| L02812505 | 25 x 0,50 mm² | 0,21 mm | 194,3 kg/km | 314 kg/km | 14,4 mm | Send inquiry |

| L02810207 | 2 x 0,75 mm² | 0,21 mm | 31,9 kg/km | 72 kg/km | 7,2 mm | Send inquiry |

| L02810307 | 3 x 0,75 mm² | 0,21 mm | 39,2 kg/km | 82 kg/km | 7,5 mm | Send inquiry |

| L02810407 | 4 x 0,75 mm² | 0,21 mm | 48,4 kg/km | 95 kg/km | 8 mm | Send inquiry |

| L02810507 | 5 x 0,75 mm² | 0,21 mm | 57,7 kg/km | 112 kg/km | 8,6 mm | Send inquiry |

| L02810707 | 7 x 0,75 mm² | 0,21 mm | 76,6 kg/km | 148 kg/km | 9,9 mm | Send inquiry |

| L02811207 | 12 x 0,75 mm² | 0,21 mm | 140,2 kg/km | 219 kg/km | 11,8 mm | Send inquiry |

| L02811807 | 18 x 0,75 mm² | 0,21 mm | 189,3 kg/km | 297 kg/km | 13,5 mm | Send inquiry |

| L02812507 | 25 x 0,75 mm² | 0,21 mm | 277,8 kg/km | 414 kg/km | 16,4 mm | Send inquiry |

| L02810210 | 2 x 1,00 mm² | 0,21 mm | 36,8 kg/km | 79 kg/km | 7,4 mm | Send inquiry |

| L02810310 | 3 x 1,00 mm² | 0,21 mm | 48,3 kg/km | 91 kg/km | 7,7 mm | Send inquiry |

| L02810410 | 4 x 1,00 mm² | 0,21 mm | 59,9 kg/km | 107 kg/km | 8,3 mm | Send inquiry |

| L02810510 | 5 x 1,00 mm² | 0,21 mm | 71,6 kg/km | 127 kg/km | 8,9 mm | Send inquiry |

| L02810710 | 7 x 1,00 mm² | 0,21 mm | 96,1 kg/km | 168 kg/km | 10,2 mm | Send inquiry |

| L02811210 | 12 x 1,00 mm² | 0,21 mm | 169,2 kg/km | 248 kg/km | 12,2 mm | Send inquiry |

| L02811810 | 18 x 1,00 mm² | 0,21 mm | 238,8 kg/km | 347 kg/km | 14,1 mm | Send inquiry |

| L02812510 | 25 x 1,00 mm² | 0,21 mm | 349,4 kg/km | 482 kg/km | 17 mm | Send inquiry |

| L02810315 | 3 x 1,50 mm² | 0,26 mm | 64,8 kg/km | 112 kg/km | 8,4 mm | Send inquiry |

| L02810415 | 4 x 1,50 mm² | 0,26 mm | 81,3 kg/km | 133 kg/km | 9 mm | Send inquiry |

| L02810515 | 5 x 1,50 mm² | 0,26 mm | 98,2 kg/km | 159 kg/km | 9,7 mm | Send inquiry |

| L02810715 | 7 x 1,50 mm² | 0,26 mm | 148,4 kg/km | 225 kg/km | 11,4 mm | Send inquiry |

| L02811215 | 12 x 1,50 mm² | 0,26 mm | 232,4 kg/km | 316 kg/km | 13,5 mm | Send inquiry |

| L02811815 | 18 x 1,50 mm² | 0,26 mm | 356,7 kg/km | 475 kg/km | 16,1 mm | Send inquiry |

| L02812515 | 25 x 1,50 mm² | 0,26 mm | 483,1 kg/km | 627 kg/km | 18,9 mm | Send inquiry |

| L02810325 | 3 x 2,50 mm² | 0,26 mm | 98,2 kg/km | 158 kg/km | 9,7 mm | Send inquiry |

| L02810425 | 4 x 2,50 mm² | 0,26 mm | 125 kg/km | 189 kg/km | 10,4 mm | Send inquiry |

| L02810525 | 5 x 2,50 mm² | 0,26 mm | 167,6 kg/km | 240 kg/km | 11,5 mm | Send inquiry |

| L02810725 | 7 x 2,50 mm² | 0,26 mm | 227,6 kg/km | 326 kg/km | 13,4 mm | Send inquiry |

| L02811225 | 12 x 2,50 mm² | 0,26 mm | 385,9 kg/km | 496 kg/km | 16,5 mm | Send inquiry |

| L02811825 | 18 x 2,50 mm² | 0,26 mm | 555,4 kg/km | 704 kg/km | 19,1 mm | Send inquiry |

| L02812525 | 25 x 2,50 mm² | 0,26 mm | 740,9 kg/km | 992 kg/km | 24,1 mm | Send inquiry |

| L02810340 | 3 x 4,00 mm² | 0,31 mm | 162,7 kg/km | 232 kg/km | 11,3 mm | Send inquiry |

| L02810440 | 4 x 4,00 mm² | 0,31 mm | 207,6 kg/km | 281 kg/km | 12,2 mm | Send inquiry |

| L02810540 | 5 x 4,00 mm² | 0,31 mm | 251,5 kg/km | 340 kg/km | 13,3 mm | Send inquiry |

| L02810360 | 3 x 6,00 mm² | 0,31 mm | 227,2 kg/km | 323 kg/km | 13,1 mm | Send inquiry |

| L02810460 | 4 x 6,00 mm² | 0,31 mm | 296,2 kg/km | 395 kg/km | 14,2 mm | Send inquiry |

| L02810560 | 5 x 6,00 mm² | 0,31 mm | 385,1 kg/km | 498 kg/km | 15,7 mm | Send inquiry |

| L02810461 | 4 x 10,0 mm² | 0,41 mm | 494,9 kg/km | 692 kg/km | 19 mm | Send inquiry |

cross section

wire-ø

± 10%

Other dimensions and colours are possible on request.