Application

RT 113 D is a PVC torsion cable with overall copper screen and a torsion angle up to +/- 270° over 0.5 m. It is recommended for use in packaging, wood working, textile, welding and cutting machine construction, car manufacturing industry, industrial robot construction, electrical drive, control, and measurement technology, construction of industrial plants and machine tooling construction.

Also suitable for applications on robots!

Outstanding features

- rugged and reliable

- torsion angle up to ± 270° over 0.5 m

- UL recognized

- PFAS-free

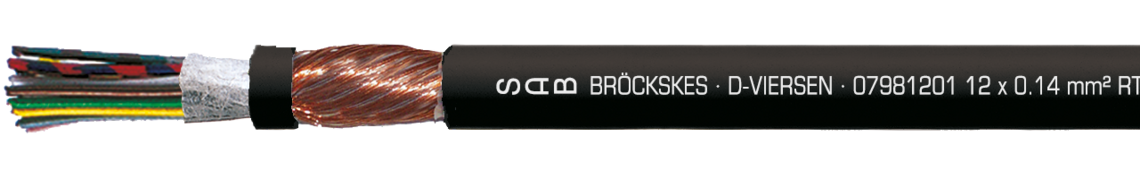

Construction

| Conductor | bare copper strands, extra fine wires |

|---|---|

| Insulation | PVC, TI2 acc. to EN 50363-3 + VDE 0207-363-3 |

| Colour code | |

| Stranding | specially adjusted layering with netting tape over each layer and one additional non-woven tape over the outer layer |

| Screen | wrapped with bare copper wires |

| Wrapping | non-woven tape |

| Sheath material | PVC, TM5 acc. to EN 50363-4-1 + VDE 0207-363-4-1 |

| Sheath colour | black (RAL 9005) |

bare copper strands, extra fine wires

PVC, TI2 acc. to EN 50363-3 + VDE 0207-363-3

specially adjusted layering with netting tape over each layer and one additional non-woven tape over the outer layer

wrapped with bare copper wires

non-woven tape

PVC, TM5 acc. to EN 50363-4-1 + VDE 0207-363-4-1

black (RAL 9005)

Technical data

| Peak operating voltage | max. 350 V |

|---|---|

| Voltage | UL: 300 V |

| Testing voltage | core/core 1500V core/screen 1200 V |

| Torsion angle | up to +/-270°/0,5 m |

| Min. bending radius | continuously flexible: 12 x d from 34 cores: 20 x d |

| Temperature range | UL: up to +80°C DIN VDE fixed laying: -40/+70°C DIN VDE flexible application: +5/+70°C |

| Fire performance | acc. to IEC 60332-1-2 + VDE 0482-332-1-2, UL VW-1 |

| Oil resistance | very good - TM5 acc. to EN 50363-4-1 + VDE 0207-363-4-1 |

| Continuous flexibility | very good |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

max. 350 V

UL: 300 V

core/core 1500V

core/screen 1200 V

up to +/-270°/0,5 m

continuously flexible: 12 x d

from 34 cores: 20 x d

UL: up to +80°C

DIN VDE fixed laying: -40/+70°C

DIN VDE flexible application: +5/+70°C

acc. to IEC 60332-1-2 + VDE 0482-332-1-2, UL VW-1

very good - TM5 acc. to EN 50363-4-1 + VDE 0207-363-4-1

very good

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section |

Largest single wire-ø | Outer-ø ± 10% | Copper figure | Cable weight ≈ | |

|---|---|---|---|---|---|---|

| L07981201 | 12 x 0,14 mm² | 0,11 mm | 8,4 mm | 32,2 kg/km | 88 kg/km | Send inquiry |

| L07982502 | 25 x 0,25 mm² | 0,11 mm | 11,6 mm | 102,3 kg/km | 201 kg/Km | Send inquiry |

cross section

wire-ø

Other dimensions and colours are possible on request.