PVC control and connection cables acc. to national and international standards

PVC control and connection cables acc. to national and international standards are for example used in the following fields: automobile industry, conveyor and automation technique, press and mold construction, tool, textile, printing and paper technique, iron and steel industry, tool and packing machine construction, CNC machining centers.

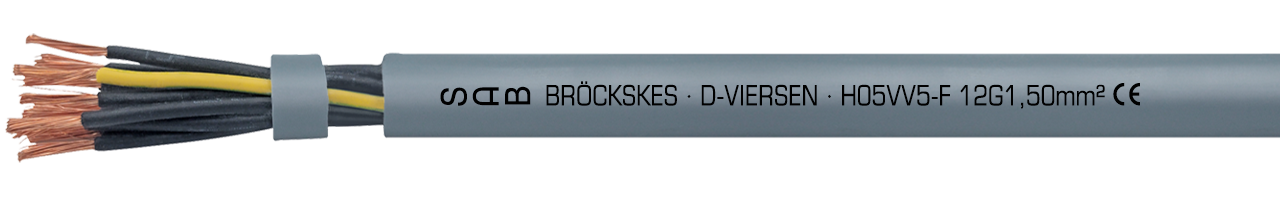

H05VV5-F

PVC control cable with numbered cores

CC 600

PVC control cable with numbered cores

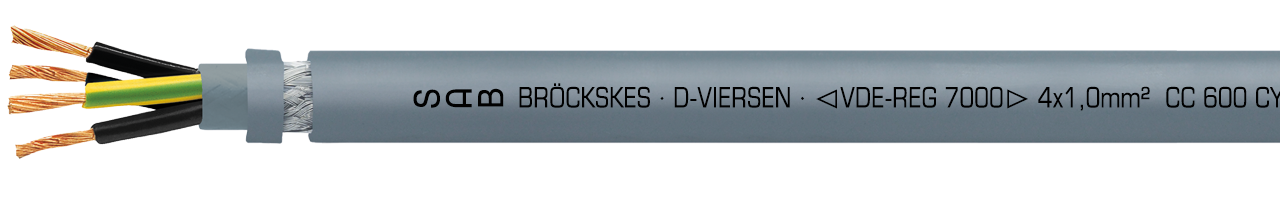

CC 600 CY

PVC control cable with numbered cores, inner sheath and overall copper screen

CC 600 T

PVC control cable with numbered cores and extended temperature range

CC 600 CY T

PVC control cable with numbered cores, extended temperature range

and overall copper screen

CC 600 MTW Typ MTW

PVC control cable and Machine-Tool Cable with numbered cores acc. to NFPA 79 for industrial machinery acc. to UL/(UL)/CSA

CC 600 MTW CY Typ MTW

PVC control cable and Machine-Tool Cable with numbered cores Type MTW and overall copper screen acc. to NFPA 79 for industrial machinery acc. to UL/(UL)/CSA