How does a Thermocouple work? Temperature Measurement with Thermocouples

Thermocouples use thermoelectricity to convert heat into electrical energy. A thermocouple is a component consisting of two different metallic conductors connected at one end. A temperature difference creates a heat flow and a thermoelectric voltage.

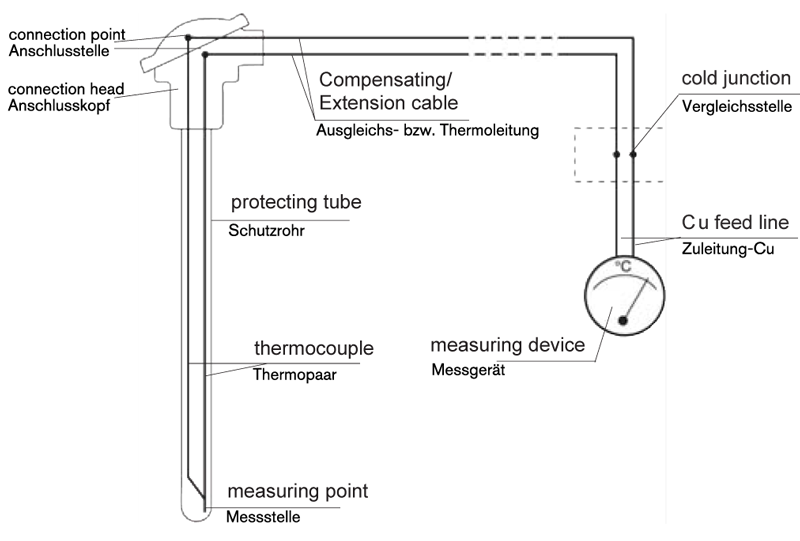

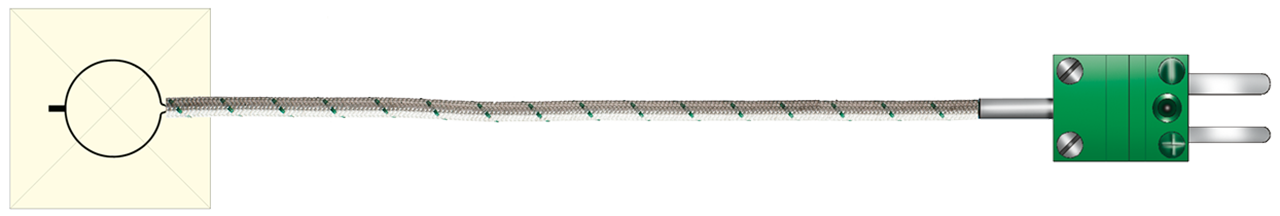

For temperature measurement with thermocouples temperature-dependent characteristics of materials have to be taken into account. These include such things as thermal expansion (expansion thermometer), the dependance of the electric resistance of metallic conductors (electrical thermometer) and electromotive force (thermocouple) etc.. A temperature measuring device with a thermocouple as a data indicator tends to consist of the thermometer itself with a measuring point, an extension cable, a cold junction with a specified constant temperature and a voltmeter.

The value of the electromotive force (EMF) produced by the thermocouple is determined by the difference between the measuring temperature and the so-called free ends of the thermocouple which are mounted in the connection head. As the connection head is usually relatively close to the measuring point, it is frequently exposed to temperature fluctuations. For this reason, a connection cable with the same thermo-electric properties as the thermocouple is used between the thermocouple and the cold junction.

Temperature as measurand

Temperature is an important factor in many areas concerning the environment, scientific research and production. It is a thermo-dynamic variable that defines the heat content of a material. Material strength changes with alternating temperature. As a consequence, the characteristics of materials have to be examined at different temperatures. To obtain a temperature value, defined temperature parameters are used. Here the parameters can be defined, for example, as the freezing and boiling points of water.

Materials for connecting cables

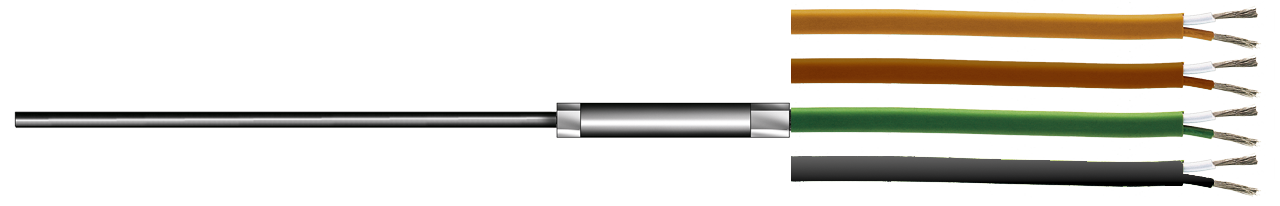

We distinguish between original materials and substitute materials. Conductors made of original materials are referred to as thermocouple cables or thermocouple cables; conductor materials made of substitute materials are referred to as compensating cables.

If you would like to find out more about the types of connecting cables, please click on the following links:

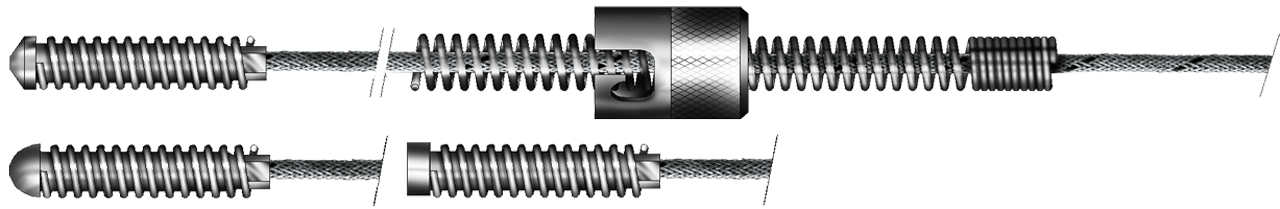

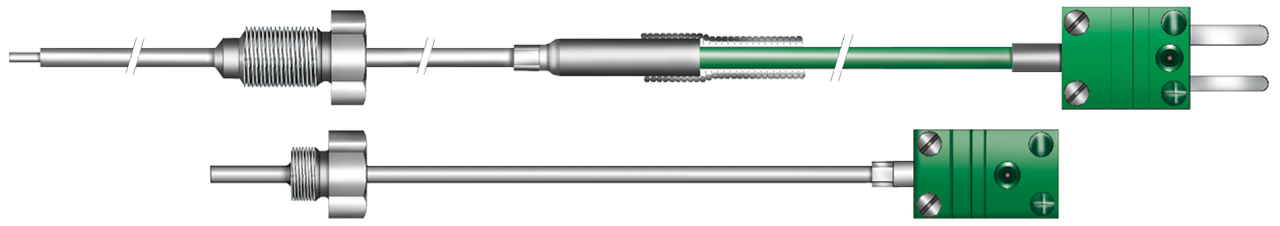

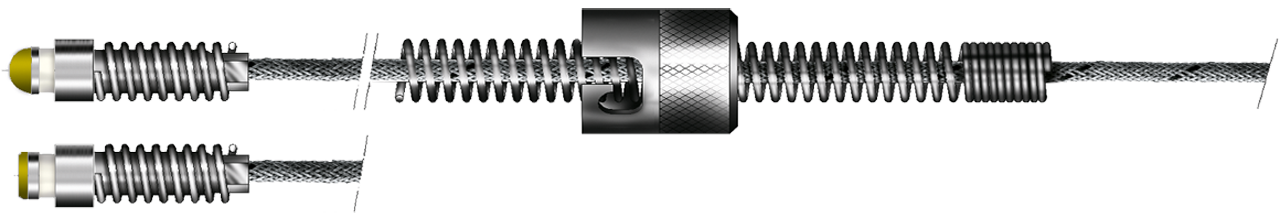

Sheathed thermocouples - basic types and construction forms

Thermocouples are available in different versions and designs. In the following overview you will find basic types of sheathed thermocouples that are frequently used depending on the application.